At 3D Juump we encourage initiatives that drive forward knowledge in industrial design and construction. Which is why we congratulate the PLMCC (Product Life Management Competency Center) for their work in initiating an international learning project of training in 3D modeling, associating three partners: Dassault Systèmes, the USTH (University of Science and Technology of Hanoi) and the French “Education Nationale”.

The objectives

The objectives of this consortium were:

- To train the local educational teams to the use of digital mockups and to practices relying on 3D graphics, CAM (Computer-aided Manufacturing), simulations and virtual development.

- To take an active part in the elaboration of training content.

- To ensure the students are guided through technical projects that correspond to the skills needed by local companies.

How was this project born?

It’s in this context, in 2007 in Brazil, that the project Blériot XI-2 Pégoud was born. In that year, the French embassy in Brazil made a call for projects to animate the Year of France in Brazil planned for 2009.

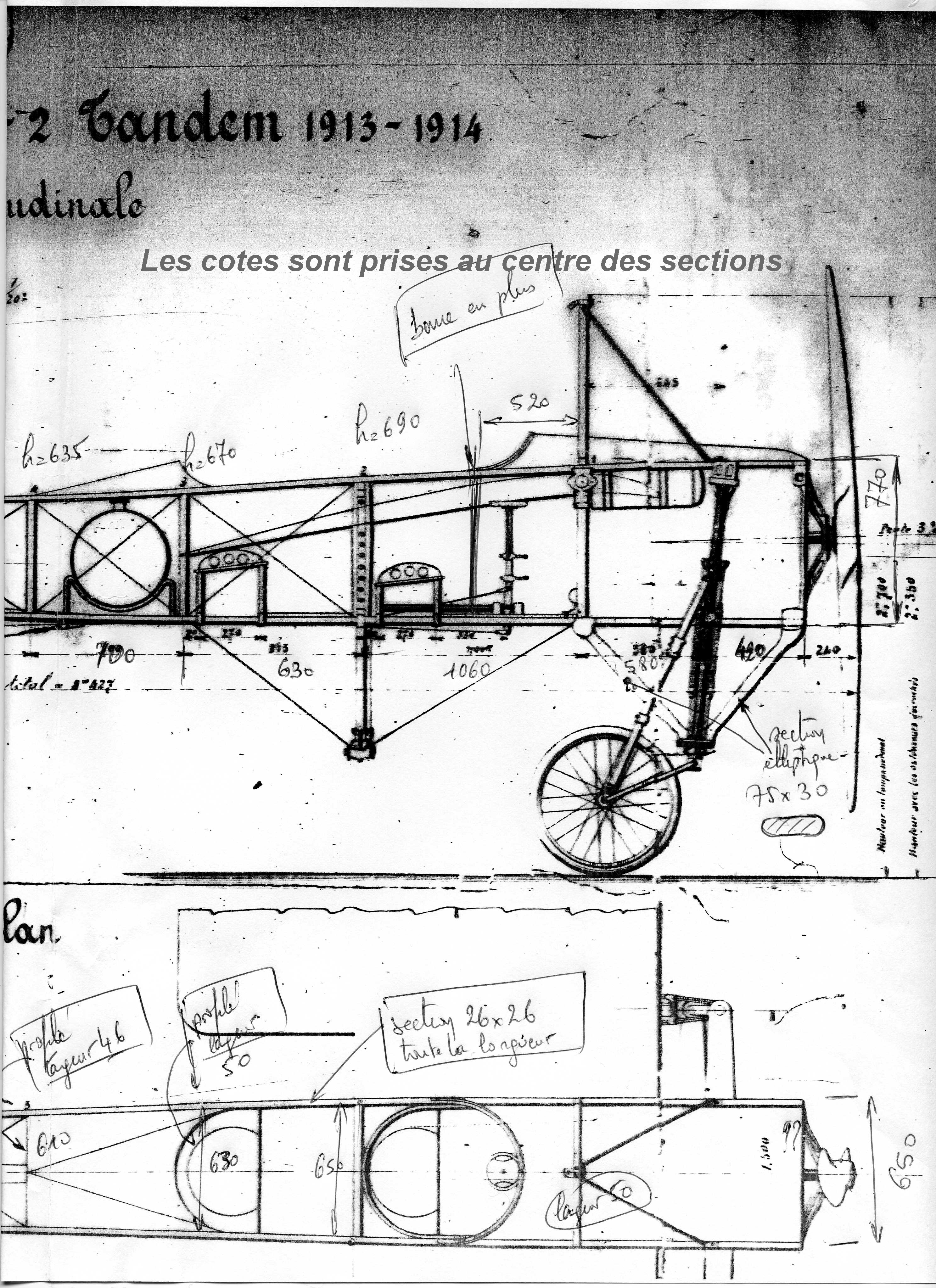

It happens that 2009 is also the hundredth anniversary of the transatlantic crossing of Louis Blériot and of the Paris Air Show (Salon du Bourget). A member of the Aéro-Club de France, who has his own collection of historical planes still in airworthy condition, then proposes to build a replica of the Blériot XI-2 Pégoud (a version chosen for its two seats, so it can take passengers and be used for initiations).

But the team that started working to build this plane quickly experiences a shortage of necessary information and detailed plans. They decide to call the PLMCC in Brazil for help to fill in this lack of information.

How does the project unfold?

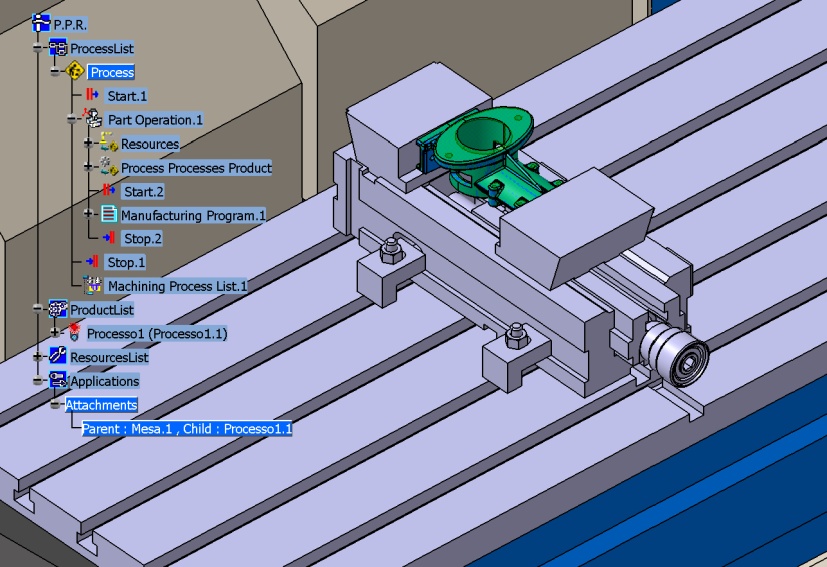

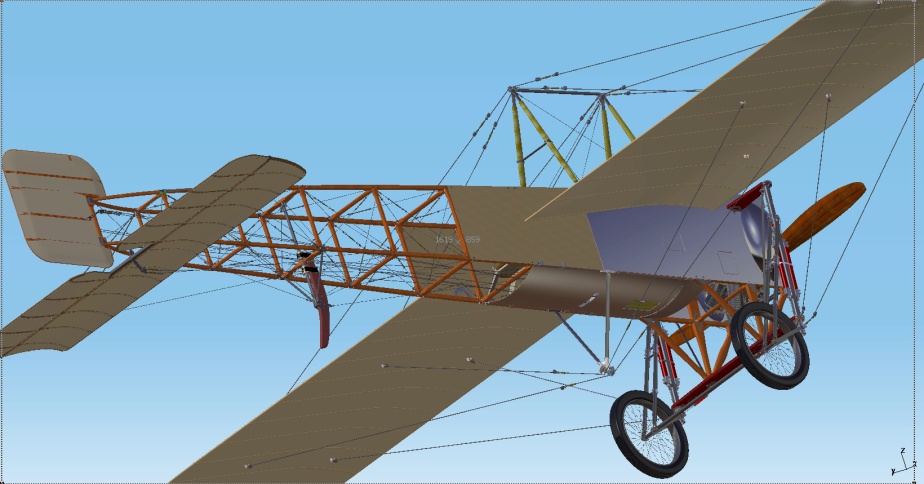

This project, which consists in redesigning and rebuilding a Blériot XI-type plane, will be made possible by collaborative and online work. Indeed, the concept of the PLM (Product Lifecycle Management) enables collaborating on a centralized digital 3D mockup through an Internet platform. This way, multiple learning centers throughout the world were able to work remotely on the same mockup by splitting the plane into sections:

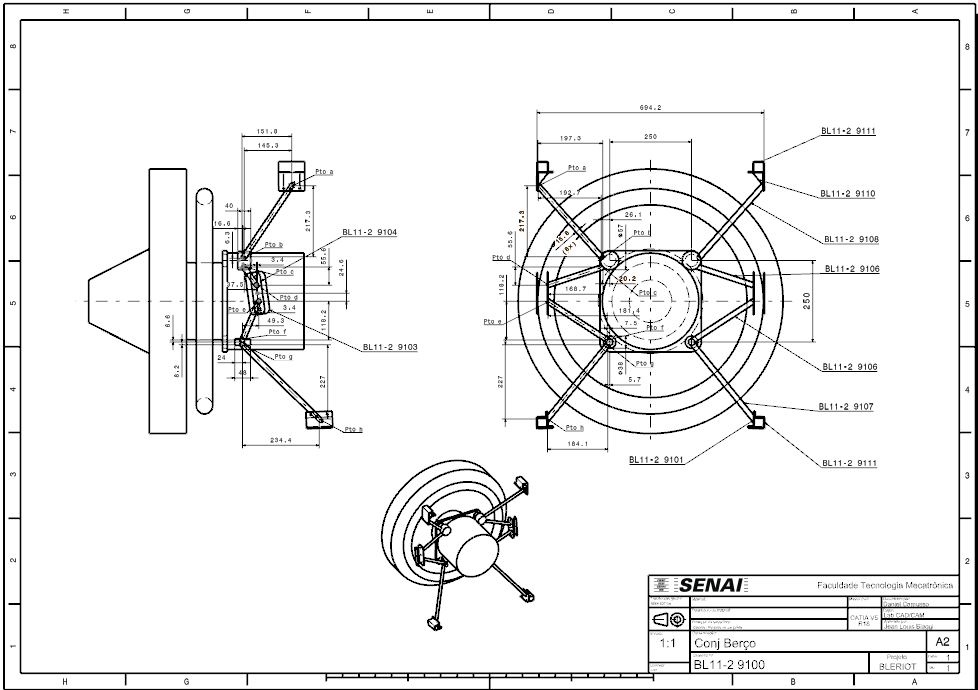

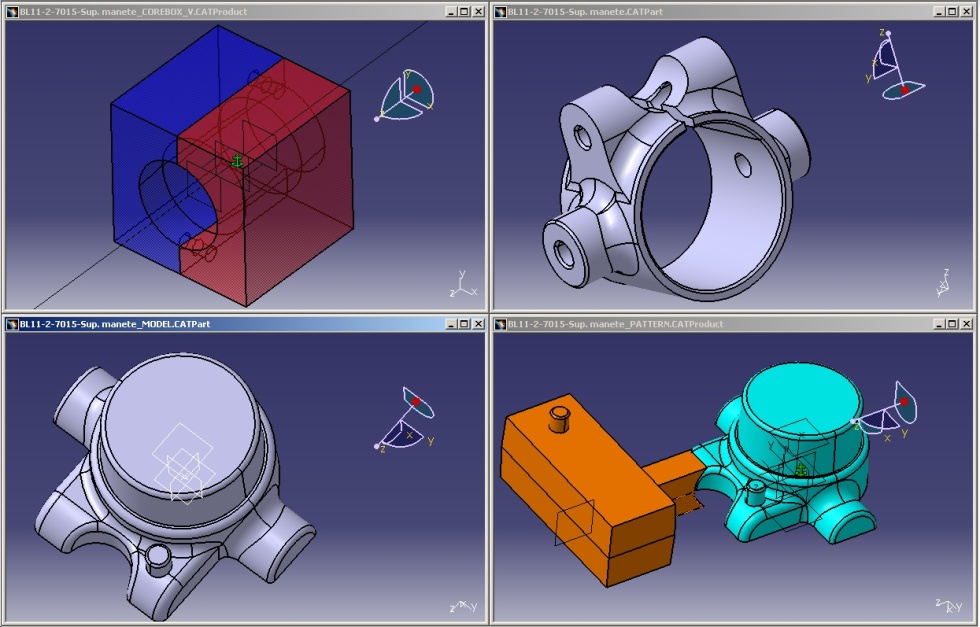

- The learning center of the SENAI and the PLMCC of Brazil worked on the fuselage, flight instruments, and the final assembly.

- The Indian PLMCC worked on the Gnome Rhône engine.

- The engineering school SupMéca in Saint Ouen and the Lycée Diderot in Paris worked simultaneously on the wings, the landing gear, the tailplane and simulations.

The mockup made of more than 3,600 parts was finished and validated in May 2008. It was presented the same year at the Broa Fly-In air show in Brazil.

Building the plane was also the fruit of collaborative work:

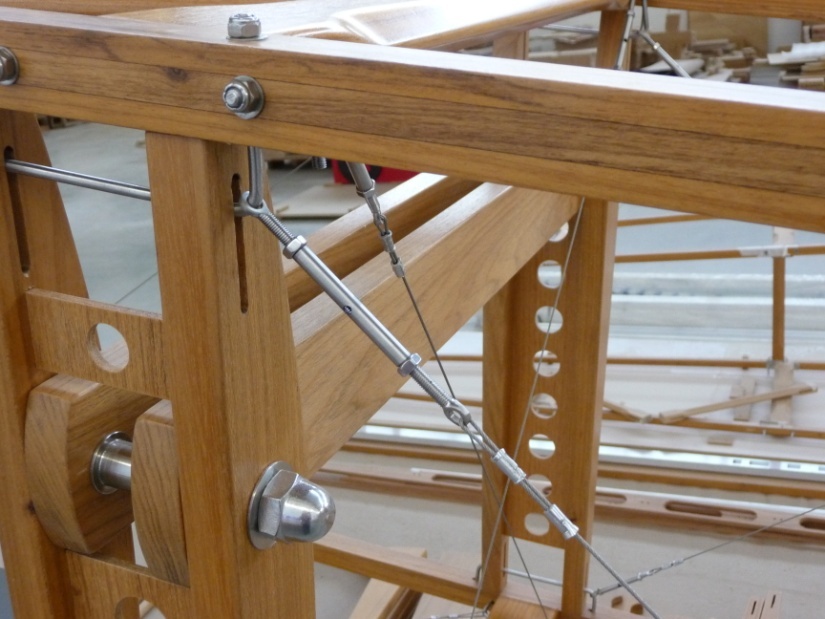

- The apprentices and teachers of the workshops of the SENAI built the metallic parts.

- The company Fenix made the wooden parts.

The outcome

The first flights of the reconstitution of the Blériot XI-2 Pégoud took place on the 10th of March 2010.

This adventure, rich in collaboration, gathered many apprentices, high-school and engineering students from three different countries along with their teachers trained by the PLMCCs.

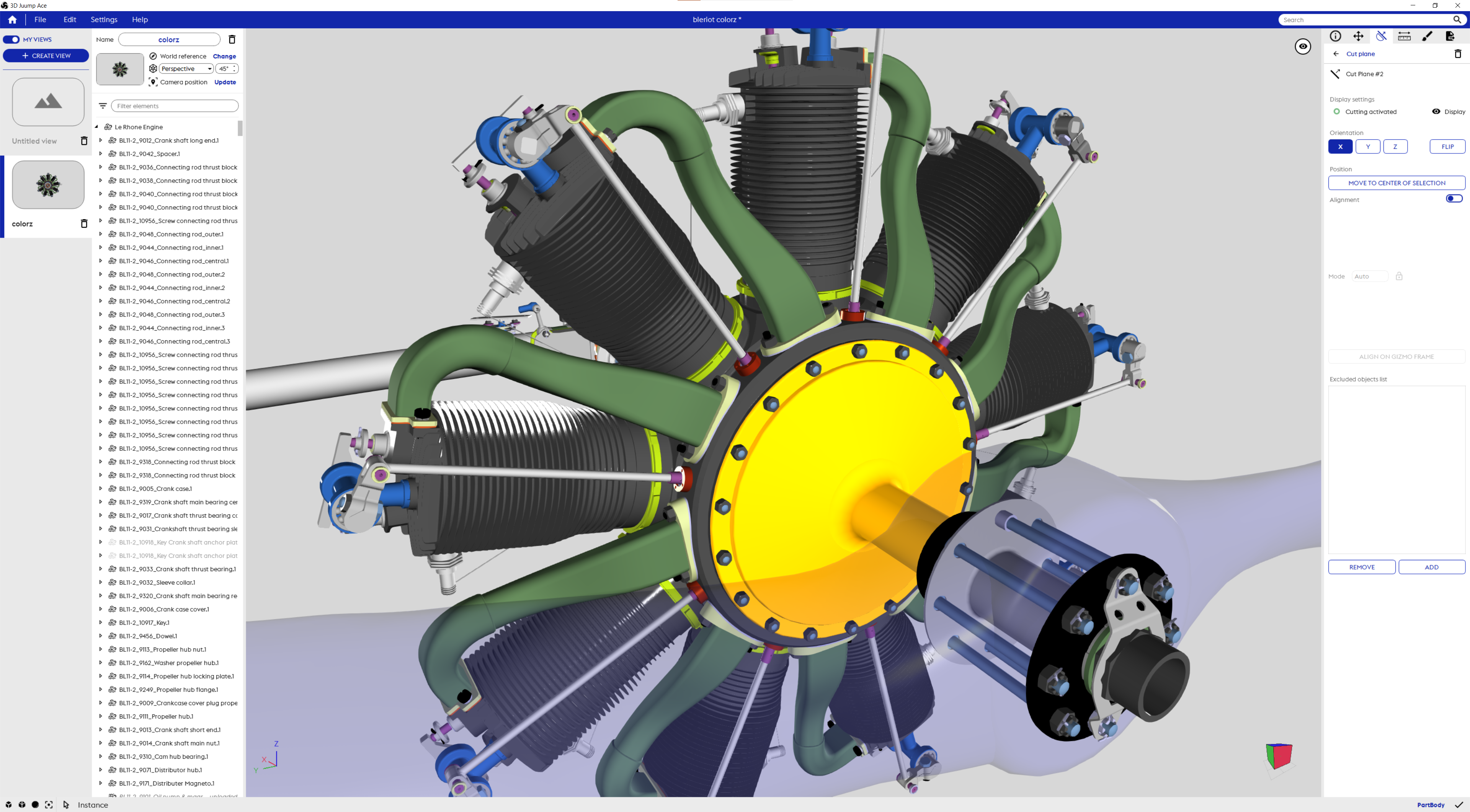

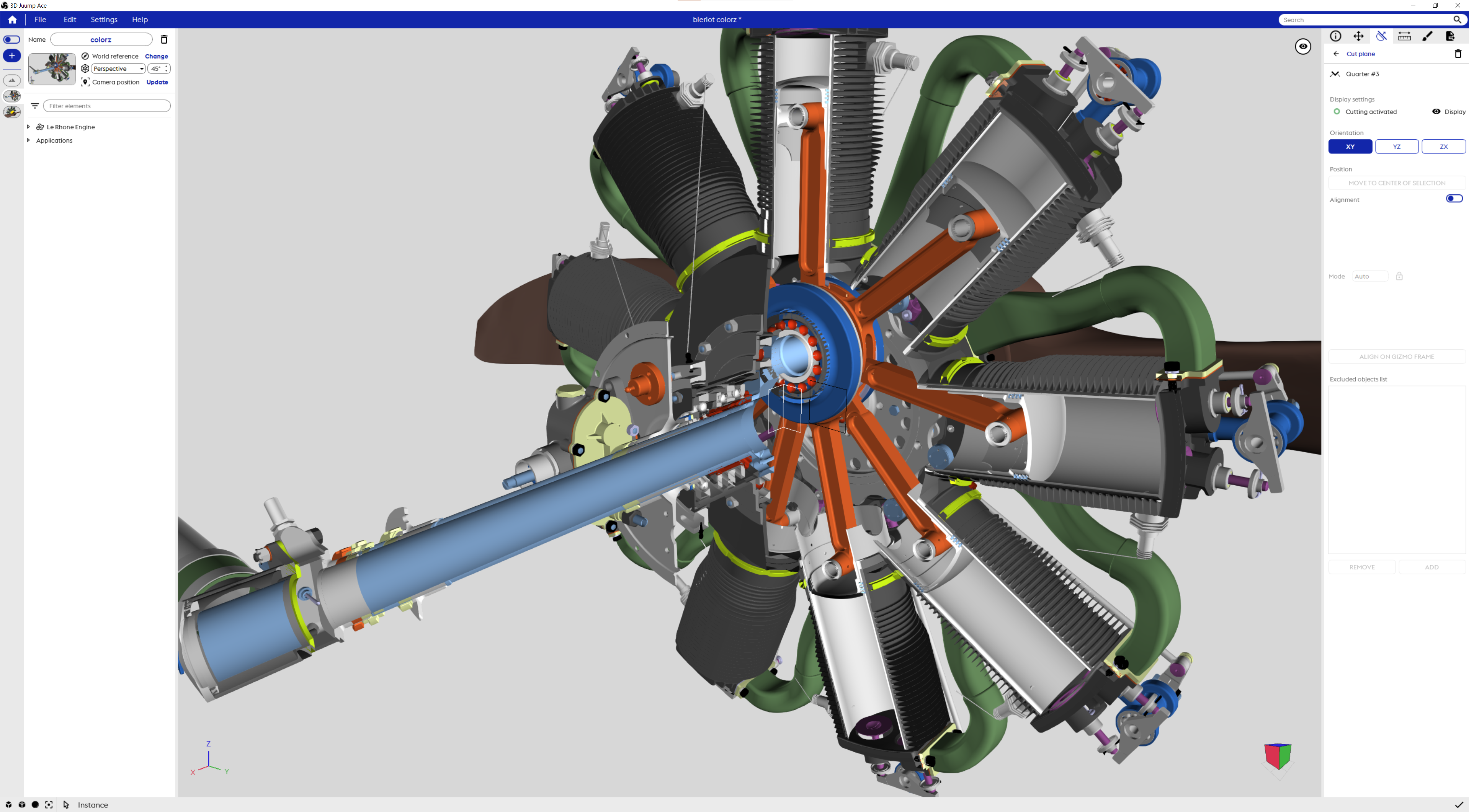

At 3D Juump, we had fun integrating and colorizing the mockup of the engine section of the plane in 3D Juump Ace. We also tidied up the metadata to obtain a fully operational mockup in a few hours. Isn’t it pretty?